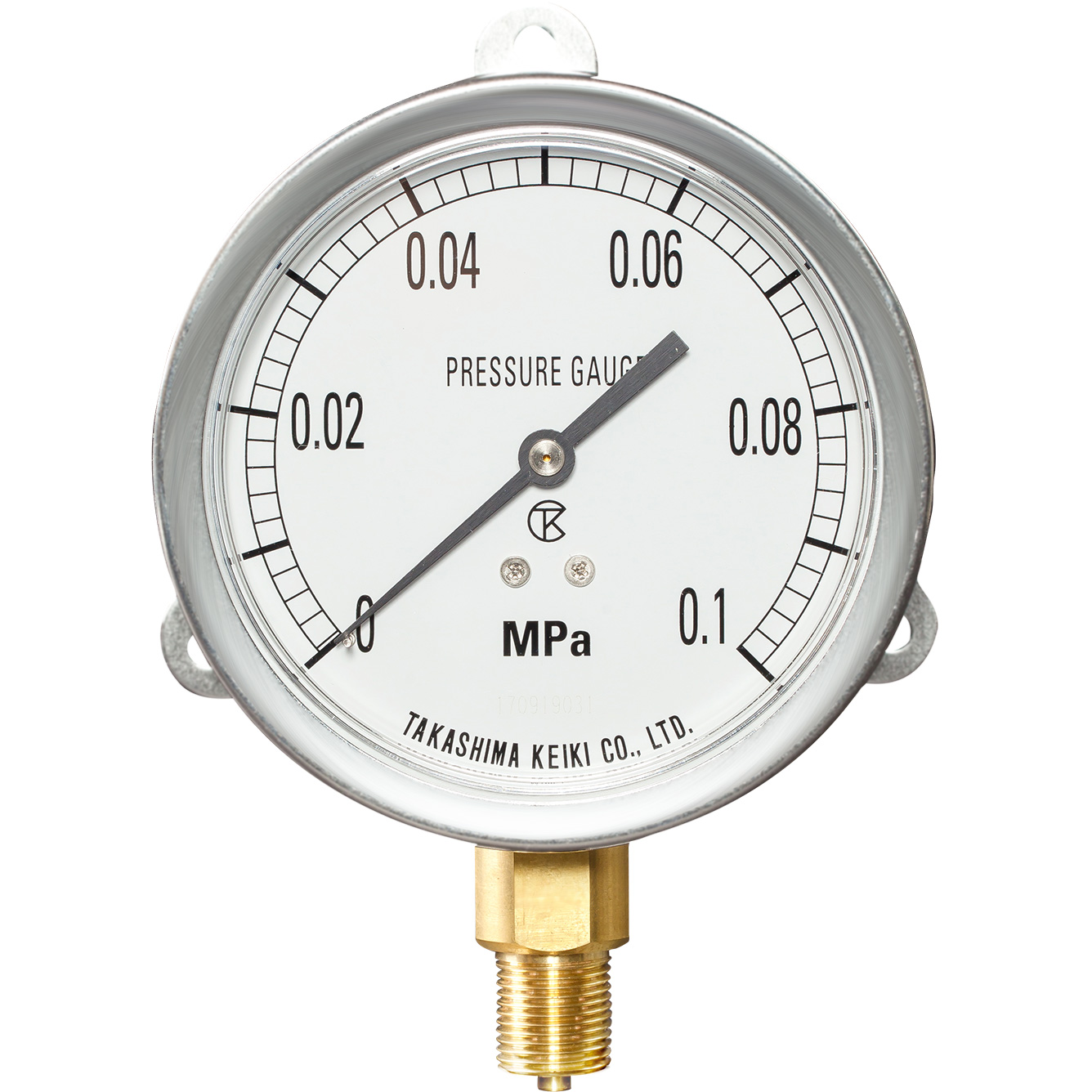

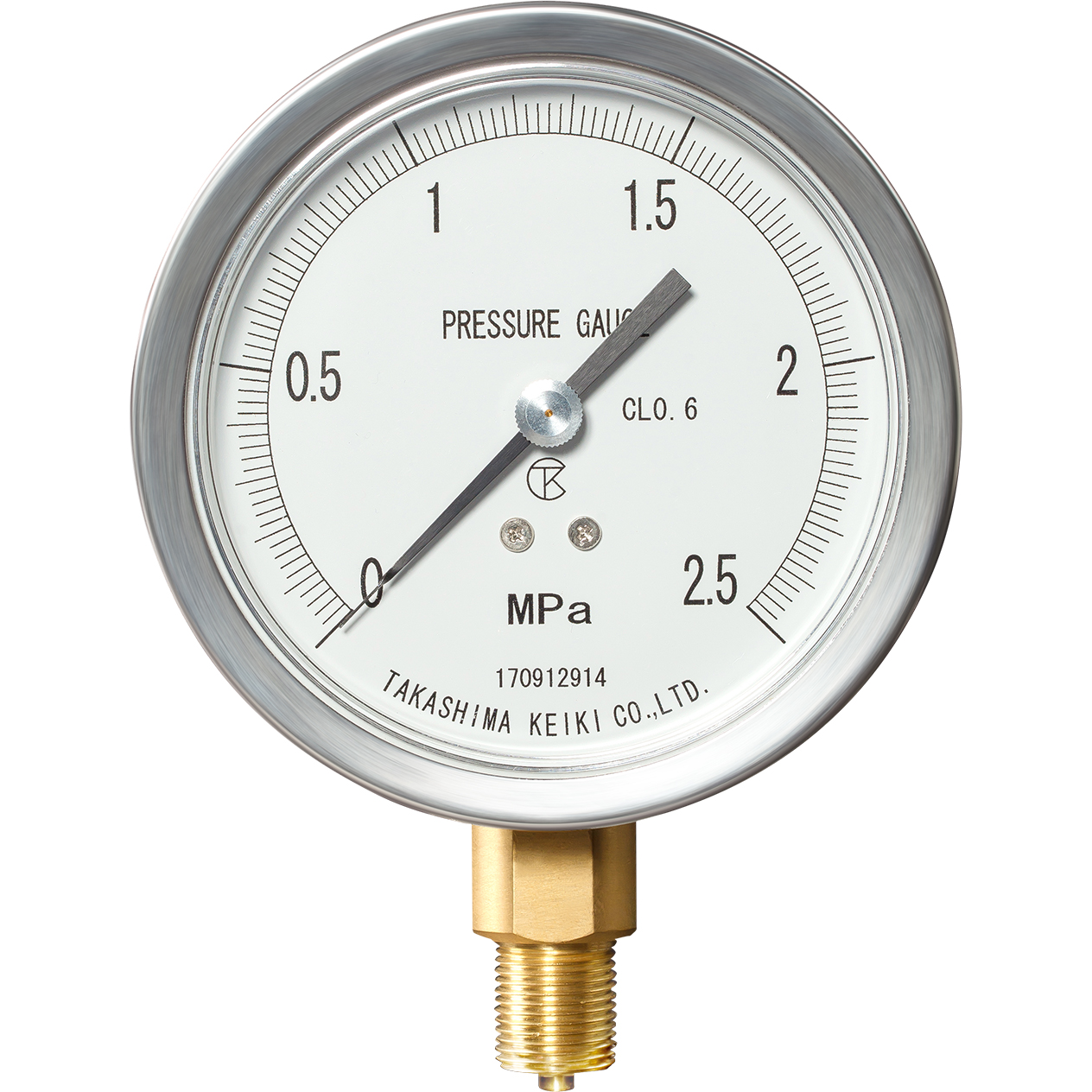

Standard Pressure Gauge ST

- As a basic pressure gauge manufactured based on JIS B 7505

- Bourdon tube pressure gauge standard, you can use this widely.

- Areliable pressure gauge with abundant production results

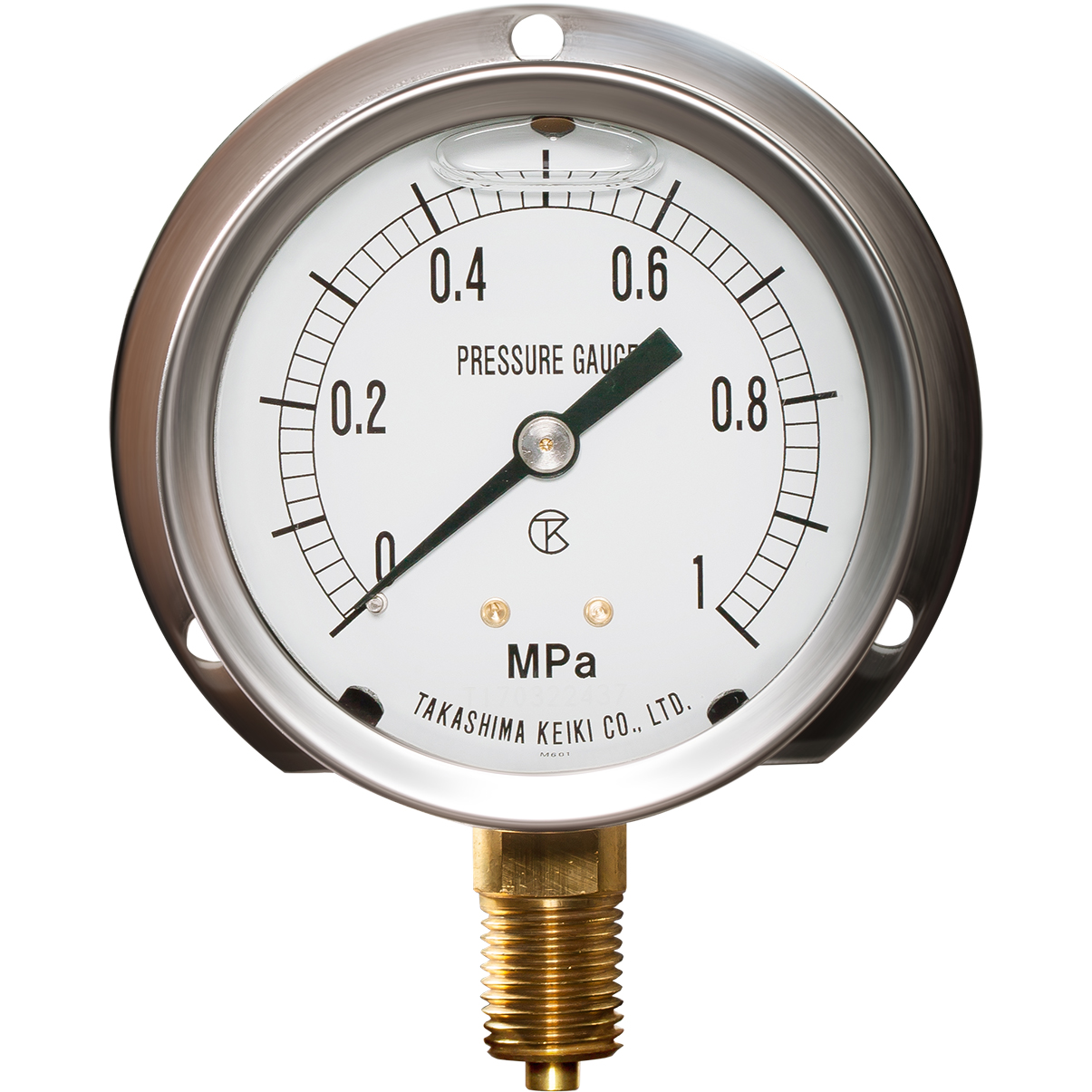

Sealing Case Pressure Gauge WP

- "Inserting an Oring or a rubber packing in the joint part to maintain stable sealing properties and protects the internal structure.

- It can be used under rain, dew conditions (IP54 equivalent).

- The ST type, which has a proven track record, has been adapted for the internal structure, inheriting its reliability.

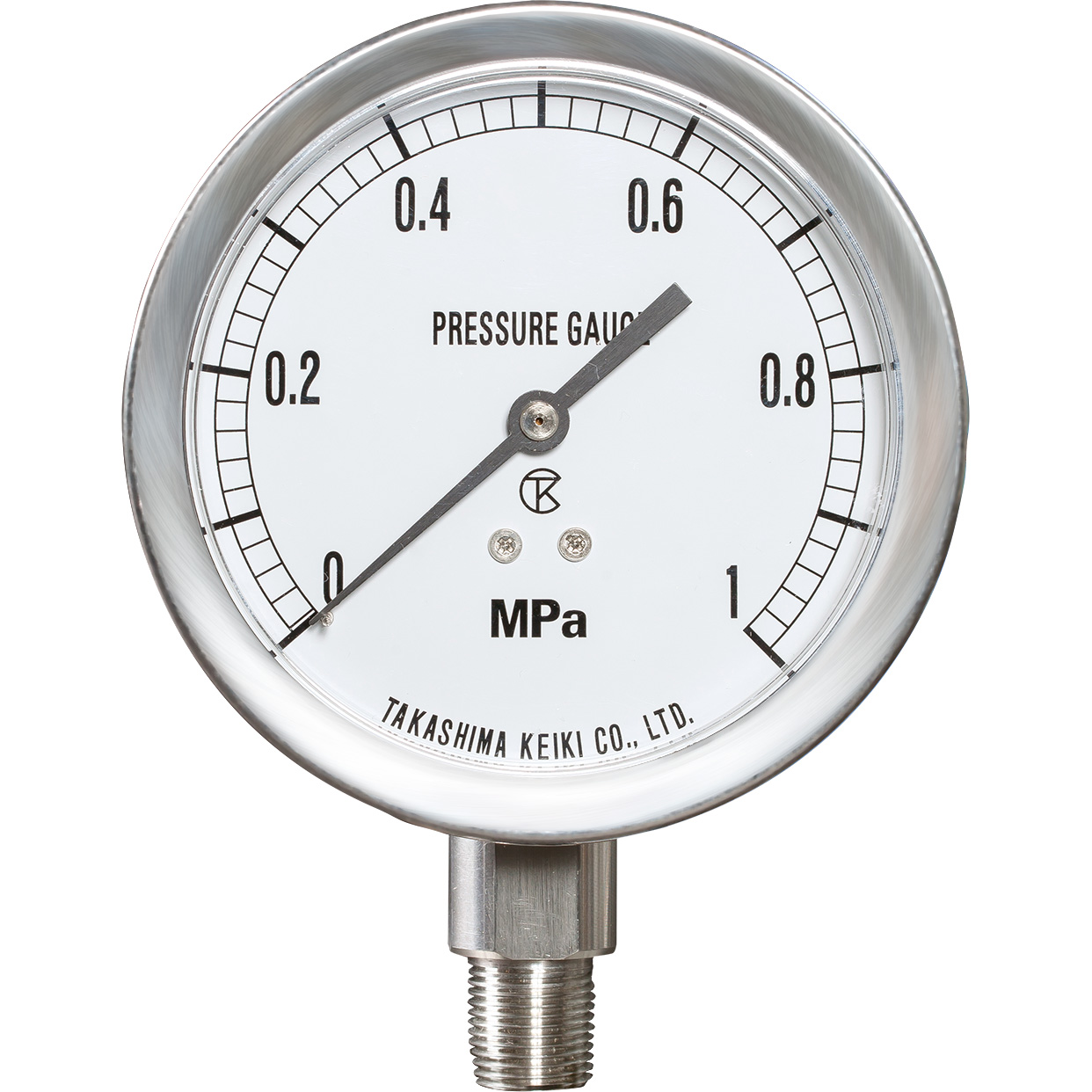

Stainless Steel Pressure Gauge WS

- All main parts are made of stainless steel (except of some parts like a dial, scale, which are not functionally necessary), it is robust and excellent corrosion resistance.

- An all-round pressure gauge with sealed structure, that can be used anywhere (IP54 equivalent).

- Electrolytic polishing is applied, it is suitable for medical and food use.

Plastic case Pressure Gauge PC

- We adopted ABS resin for the case and made it cost-effective.

- Ideal for rust-prone places such as in the water use sections that do not require so tight sealability than where a closed type is needed.

Glycerin filled Pressure Gauge GR

-To protect the internal mechanism and ensure excellent durability and vibration resistance, glycerin is encapsulated inside the pressure gauge.

-Ideal for places of violent vibration and pulsation, which were considered impossible with a pressure gauge.

Pressure Gauge with Electric Contacts (Micro Switch Type) MS

- The adapted micro switch is a proven standard from and it imporoved the reliability.

- When set pressure is reached, it activates switch to use for alarm or control.

Bimetal Thermometer (Standard Type) BS

- Simple structure and high durability.

- Easy to use and low cost.

- Safety due to no sealing liquid and gas used.

- Wide range of size and appearance are available for designing because of direct indication of bimetal displacement.

Bimetal Thermometer (Stainless Sealing Type) BW

- Drip-proof, dust proof structure equivalent to IP52.

- Simple structure and high durability.

- Easy to use and low cost.

- Safety due to no sealing liquid and gas used.

- Wide range of size and appearance are available for designing because of direct indication of bimetal displacement.

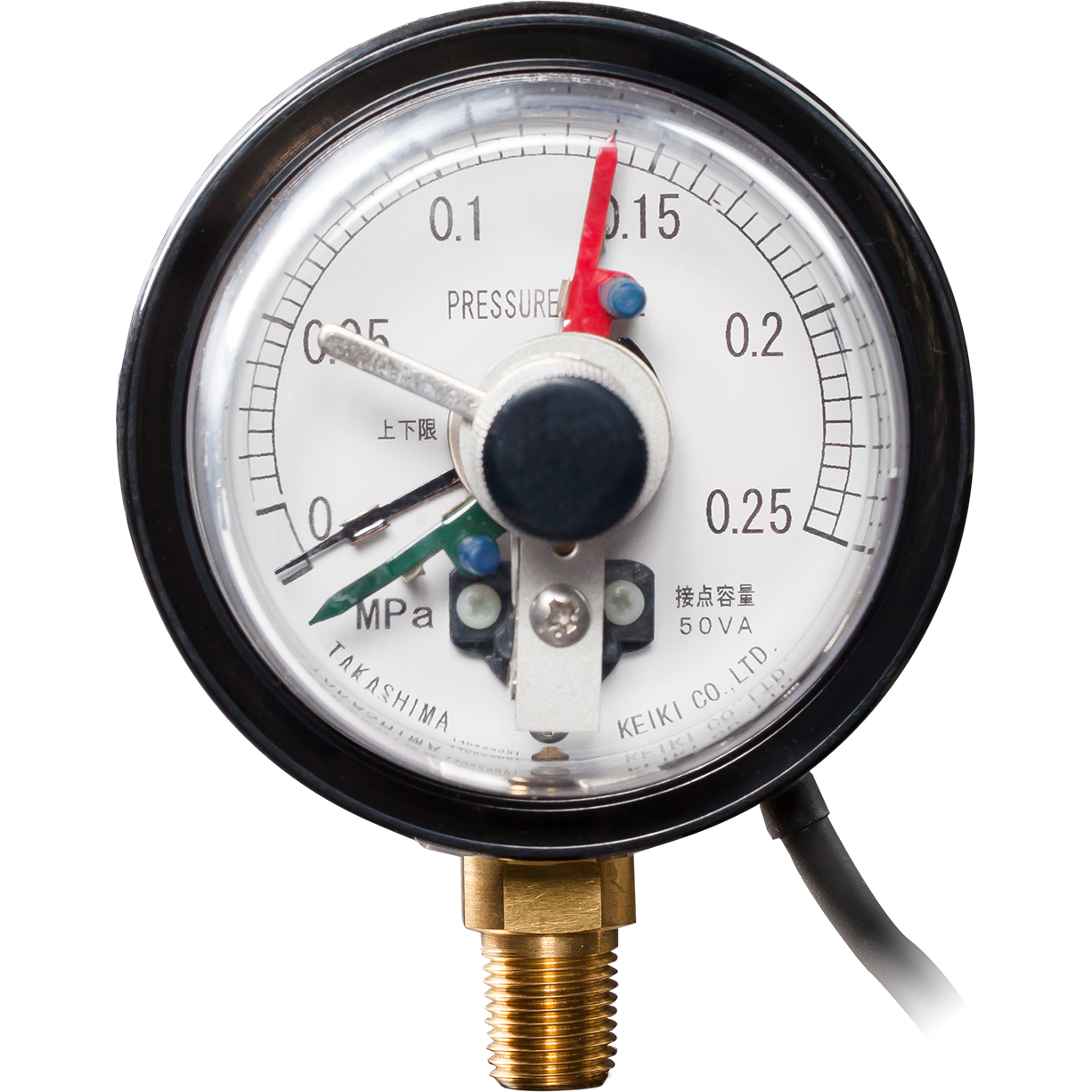

Pressure Gauge with Electric Contacts (Contact Switch Type) CS

- When set pressure is reached, it activates switch to use for alarm or control.

Small Size Pressure Gauge KG

- "Compact pressure gauge perfect for incorporation into a machine or equipment."

- The maximum pressure range is ultra-wide, with 0.1 to 40 Mpa (size 40, 50) and it covers from " pneumatic equipment to high pressure hydraulic equipment."

- We can respond flexibly to custom made requests such as name insertion and special additional processing.

Twin Needle Pressure Gauge DP

- Space saving by measuring two pressures simultaneously in one pressure gauge.

- It is perfect to display compared two pressures.

Differential Pressure Gauge DF

- Indicate pressure difference between 2 points

- Measurement of flow rate, measurement of clogging of filter, measurement of internal and external pressure difference in clean room

Gear-less Pressure Gauge (Link Type) RS

- A pressure gauge that does not use gears for the enlarging mechanism and improves durability.

- The link formula instructs the displacement of the Bourdon tube to the pointer using the link.

Gear-less Pressure Gauge (Spiral Type) SP

- A pressure gauge that does not use gears for the enlarging mechanism and improves durability

- The spiral type winds the Bourdon tube a number of times to set the pointer and directs the pressure.

- Spiral type has marvelous durability because of no sliding part, therefore ultra miniaturization can be realized.

- It is used for pulsating pressure measurement of a Plunger type pump and a portable cylinder for aircraft.

Micromanometer (Indoor use Type) MP1

- It is used for low pressure measurement which can not be taken with an ordinary pressure gauge of 60 kPa (6000 mmH2O) or less.

Micromanometer (Drip-proofed Type ) MP2

- It is used for low pressure measurement which can not be taken with an ordinary pressure gauge of 60 kPa (6000 mmH2O) or less.

- The case is drip-proofed (IP 22 equivalent).

SUS Bellows Gauge Micronanometer MP3 Type

・It is used for low pressure measurement which can not be taken with an ordinary pressure gauge of 60 kPa(6000 mmH2o) or less.

Pressure Gauge for General Gas OG

- It is used for gas pressure measurement of oxygen, acetylene, hydrogen, helium, etc.

- Gas leak test, adoption of safety blowhole and self-extinguishing resin and thorough safety measures.

- Completely dry treatment that does not emit any harmful water or oil to connected equipment such as pressure regulator.

Pressure Gauge for High purity Gas HC

- It is used for gas pressure measurement of oxygen, acetylene, hydrogen, helium, etc.

- Gas leakage test, safety blowhole and self-extinguishing resin , adopted thorough safety measures.

- Completely dry treatment does not emit any harmful water or oil into connected equipment such as pressure regulator.

- For high-purity gases, airtightness and cleanliness are fully considered, making it ideal for semiconductor process.

Pressure Gauge for High pressure gas HP

- It is used for gas pressure measurement of oxygen, acetylene, hydrogen, helium, etc.

- Gas leakage test, safety blowhole and self-extinguishing resin, adopted thorough safety measures.

- Completely dry treatment does not emit any harmful water or oil into connected equipment such as pressure regulator.

- The structure for high pressure gas is made of hydrogen-conscious material and has a bulkhead which allows the Bourbon tube movement backward in case of rupture as a safety measure.

Diaphragm Pressure Gauge (Direct Connection Type) SA

- Provided a diaphragm so that fluid does not enter directly into the pressure gauge.

- For the measurement of corrosive fluid, high viscosity fluid in chemical plants, food factories, etc.

- No oil treatment is done for all models.

Diaphragm Pressure Gauge (Remote Sensing B Type) SB

- Provided a diaphragm so that fluid does not enter directly into the pressure gauge.

- For the measurement of corrosive fluid, high viscosity fluid in chemical plants, food factories, etc.

- Possible to separate the pressure receiving part and the indicating part as a separate type.

- No oil treatment is done for all models.

Diaphragm Pressure Gauge (Remote Sensing D Type) SD

- Provided a diaphragm so that fluid does not enter directly into the pressure gauge.

- For the measurement of corrosive fluid, high viscosity fluid in chemical plants, food factories, etc.

- Possible to separate the pressure receiving part and the indicating part as a separate type.

- No oil treatment is done for all models.

Bimetal Thermometer (Small-sized Type) BK

- Simple structure and high durability.

- Easy to use and low cost.

- Safety due to no sealing liquid and gas used.

- Wide range of size and appearance are available for designing because of direct indication of bimetal displacement.

Water Pressure Temperature Gauge PB

- Both water pressure (volume) and temperature measurable by all-in-one gauge

- Easy to install and maintain by connecting protective tube with valve.

- Capable to measure pressure and temperature of various type of machine at same time due to improvement of corrosion resistance by using stainless steel for all portions.

Throttle Screw FS

- Fixed type diaphragm which is attached directly to the pressure inflow port of the pressure gauge to protect the pressure gauge by alleviating the pulsating pressure.

Dampener KD

- Variable adjustment type diaphragm which relieves impact and protects the pressure gauge.

Marker Pointer -

- A mark attached to know the management pressure at glance when pressure management being performed.

Pressure reducing valve RV

・It controls to constant pressure by reducing the pressure of air, carbon dioxide gas, nitrogen gas, etc.

・Compact design, fixed control pressure type and adjustable type are available.

Pressure Switch TS1, TS2, MPS

- Reliable switch using microswitch as contact

- No leak type using a bellows or a Bourdon tube and a high pressure type using a piston as a pressure receiving element are available.

Products

- Standard Pressure Gauge ST

- Sealing Case Pressure Gauge WP

- Stainless Steel Pressure Gauge WS

- Plastic case Pressure Gauge PC

- Glycerin filled Pressure Gauge GR

- Pressure Gauge with Electric Contacts (Micro Switch Type) MS

- Bimetal Thermometer (Standard Type) BS

- Bimetal Thermometer (Stainless Sealing Type) BW

- Pressure Gauge with Electric Contacts (Contact Switch Type) CS

- Small Size Pressure Gauge KG

- Twin Needle Pressure Gauge DP

- Differential Pressure Gauge DF

- Gear-less Pressure Gauge (Link Type) RS

- Gear-less Pressure Gauge (Spiral Type) SP

- Micromanometer (Indoor use Type) MP1

- Micromanometer (Drip-proofed Type ) MP2

- SUS Bellows Gauge Micronanometer MP3 Type

- Pressure Gauge for General Gas OG

- Pressure Gauge for High purity Gas HC

- Pressure Gauge for High pressure gas HP

- Diaphragm Pressure Gauge (Direct Connection Type) SA

- Diaphragm Pressure Gauge (Remote Sensing B Type) SB

- Diaphragm Pressure Gauge (Remote Sensing D Type) SD

- Pressure Gauge 0.6 Class MA

- Bimetal Thermometer (Small-sized Type) BK

- Water Pressure Temperature Gauge PB

- Throttle Screw FS

- Dampener KD

- Joint KJ

- Siphon Pipe SO, SU

- GaugeBall Cock KC

- Gauge Valve VS, VL

- Packing KP

- Marker Pointer -

- Pressure reducing valve RV

- Pressure Switch TS1, TS2, MPS

We design, arrange and manufacture.

Pressure gauge, thermo sensors, thermometer,

and other related products.

Tel. +81-266-54-3312